Piedmont Tech Introduces Advanced Welding Certificate

Piedmont Technical College (PTC) Welding Program Director Jim Ladd knows you can’t start a fire without a spark. Not everyone who signs up for welding begins carrying a passionate fire for the profession. Sometimes the best way to approach it is in calculated steps. That’s why PTC this fall is introducing a new Advanced Welding Certificate, which moves students into the workplace sooner so they can practice their craft while contemplating whether to continue to an associate degree.

“We saw a big number of students who were really successful in our welding classes but left the program to enter the workforce before earning their degree,” Ladd said. “There is a shortage of qualified welders. Employers just want welders who can do the job. The Advanced Welding Certificate demonstrates that they have received formal training, which gets their foot in the door.”

“We saw a big number of students who were really successful in our welding classes but left the program to enter the workforce before earning their degree,” Ladd said. “There is a shortage of qualified welders. Employers just want welders who can do the job. The Advanced Welding Certificate demonstrates that they have received formal training, which gets their foot in the door.”

The new certificate is designed as part of a series of incremental welding credentials, with students earning a specific certificate each semester of the program. “We structure it so that, in the first semester, the students can obtain the basic welding certificate,” Ladd said. “Welding is a building process, so each credential is a step in the process. … That is going to be a big draw for our program.”

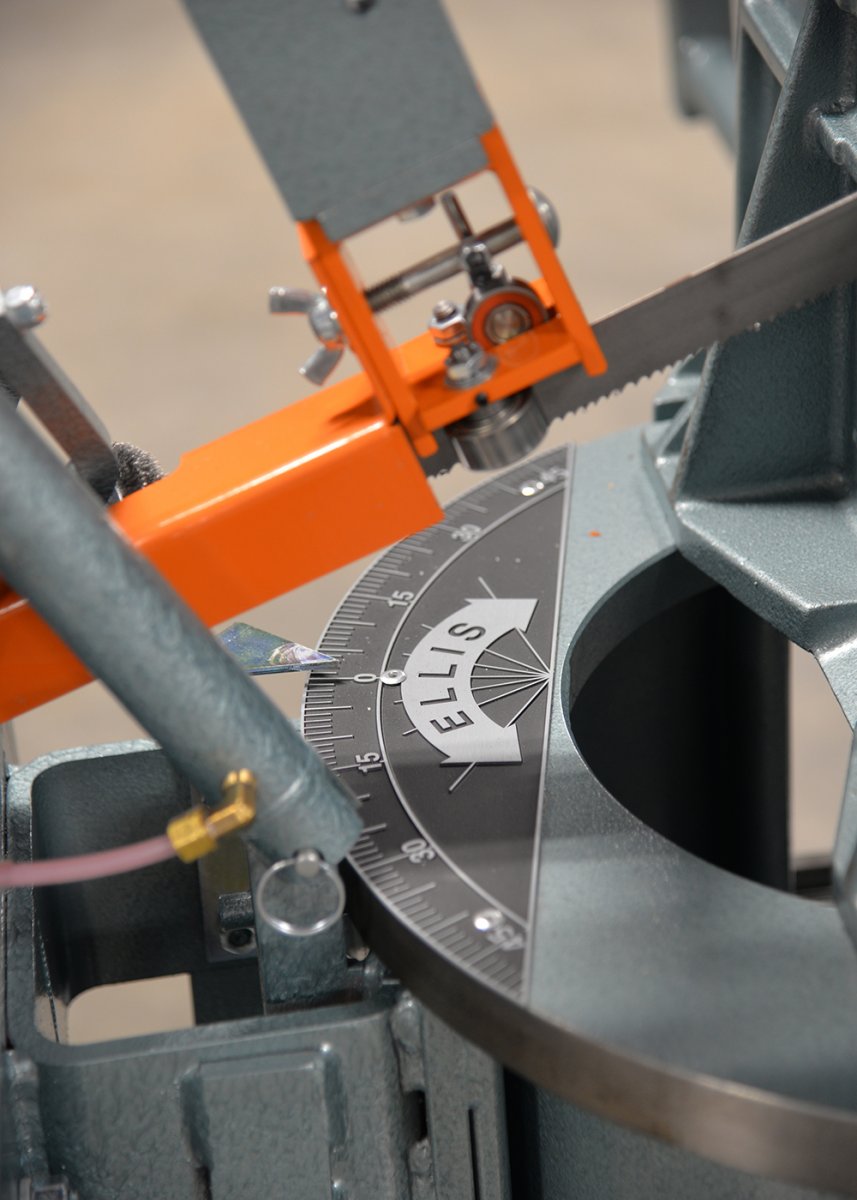

Ladd is pleased that students will begin accessing the college’s new welding lab housed in the William H. “Billy” O’Dell Center for Manufacturing Excellence when it opens later this fall. The new facility features 45 fully outfitted, state-of-the-art welding booths. One highlight is an industrial-grade, computer-controlled plasma cutting table, which eliminates any shake from hand-held cutting torches. Also on the lab floor is a top-of-the-line metering band saw with a built-in protractor to facilitate perfectly angled cuts.

Ladd is pleased that students will begin accessing the college’s new welding lab housed in the William H. “Billy” O’Dell Center for Manufacturing Excellence when it opens later this fall. The new facility features 45 fully outfitted, state-of-the-art welding booths. One highlight is an industrial-grade, computer-controlled plasma cutting table, which eliminates any shake from hand-held cutting torches. Also on the lab floor is a top-of-the-line metering band saw with a built-in protractor to facilitate perfectly angled cuts.

“We are excited about moving to the new facility,” he said. “These machines are the best, top-of-the-line welding machines anywhere.”

“We are excited about moving to the new facility,” he said. “These machines are the best, top-of-the-line welding machines anywhere.”

PTC student Austin Hamlett chose to study welding at PTC after learning about last-dollar scholarship assistance available from The Greenwood Promise when he was still attending Greenwood High School.

“I didn’t want to go to a four-year college because it costs a ton of money,” he said. “I don’t want to have debt coming out of school. I felt it was a lot safer and smarter to go to Piedmont Tech.”

Industries that consistently need qualified welders include manufacturing, automotive and construction. With the nation’s infrastructure rapidly aging, the demand for welders and those with related skills is expected to grow substantially. Because basic welding skills are fairly similar across industries, welders enjoy the versatility to shift from one industry to another, which maximizes their employability. Meanwhile, Hamlett is making incremental plans for his future.

“In the beginning, I want to work for someone to get the basic experience down,” Hamlett said. “Then my uncle has his own contracting business, and he can contract jobs to me. My end goal is to run my own crew.”

For more information about the Welding Program at PTC, visit www.ptc.edu/welding.

PHOTOS:

A row of newly installed welding booths at the O’Dell Center

Welding Program Director Jim Ladd oversees preparation of the new welding lab.

The new lab features this industrial-grade CNC plasma cutting table.

Students will be able to work with this metering band saw to make perfectly angled cuts.

###